In the ever changing world of civil engineering and construction in 2026, simbramento has emerged as a buzzword that describes modern (and dare I say sexy) support systems for concrete forms. Frequently used as a synonym for or variation of “cimbramento” in Portuguese-speaking countries and international projects, simbramento is a way to call the them temporary structural systems that are indispensable during pouring and curing operations of concrete. In modern times, with countries all over the world investing in infrastructure including urban development, bridge construction and high-rise building, knowledge of simbramento is also important for engineers, contractors and project managers who are interested in accuracy and safety.

This extensive paper takes a good look at the details of simbramento, discussing its definitions, changes over time, types, practices to apply them in the practice, safety precautions and comparisons and then evaluating real-world examples of it used as well as suggesting future research paths. Whether you’re an experienced pro looking for more refinements or a beginner who’s typed simbramento into Google simply because you were curious, this guide —based on industry practice and expert opinion—will give you actionable information. We’ll organize this with in-depth paragraphs on every issue, followed by an extensive FAQ section to answer the common questions.

What Is Simbramento? A Fundamental Overview

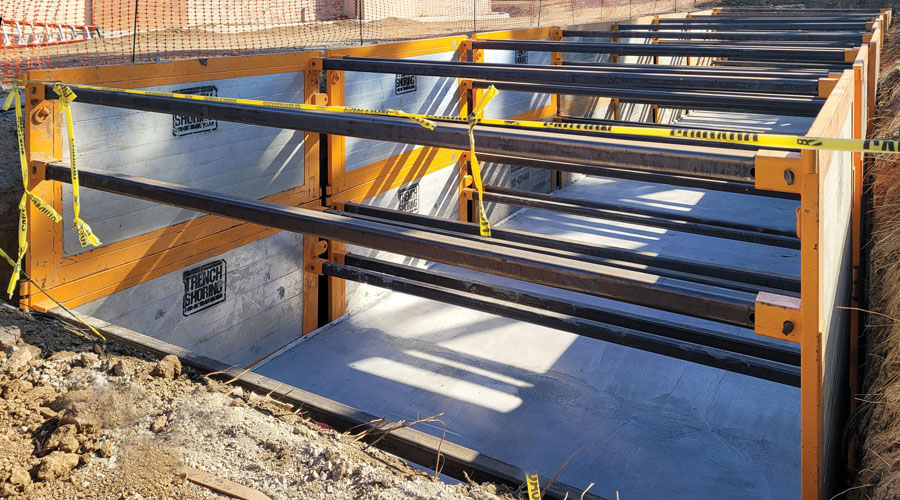

Durante il getto fresco, l’infrastruttura del simbramento è tuttavia necessaria come supporto temporaneo di appoggio della c.a. fresca e dei casseri in fase di lavorazione allorquando sarà raggiunto il tenore caratteristico dell’attitudine indipendente. In the jargon of the art, it is the totality of design features that resist distortion or failure during the critical curing period. It comprises a plurality of vertical props, horizontal beams and bracing members which are most commonly manufactured from timber, metal or advanced composites.

“We use simbramento, stems we put in today and pull out tomorrow.” Unlike the permanent bits of structure, simbramento is transient but essential. It helps keep your slabs, beams and other horizontal forms in place when you are setting concrete. By 2026, sustainable building practices are on the rise; simbramento systems make use of more reusable materials, including aluminum and steel alloys which decrease waste and save costs in large-scale works.

“Simbramento” may derive from Portuguese or Spanish regional variations of construction jargon, where it points to the “shoring” or “propping”. For example, in Brazilian and Portuguese engineering lexicon is often found in conjunction with “escoramento,” but simbramento emphasizes the whole framework instead of just separate supports. This is an important feature in multilingual project teams because misunderstandings could cause unsafe situations.

On a practical level, simbramento starts with site assessment: Engineers calculate loads from the weight of concrete, live loads such as workers and environmental conditions like wind or seismic events. In 2026, cutting-edge computer software, including Building Information Modeling (BIM) tools, allows these loads to be simulated in order for simbramento designs to achieve their”lightness”, using a minimum quantity of material while maintaining equilibrium.

Distinguishing Between Simbramento and Escoramento

There is another term that causes confusion, simbramento which over time came to define escoramento. Both have supporting structures built into them, but escoramento usually refers to just the vertical propping elements themselves — when you think of those steel props or towers that hold the formwork up directly, this is what it means. Simbramento is wider, encompassing the whole system including escoramento at escoramento più puntoni horizontal girders, diagonals braces talvolta anche reescoramento (secondario al distacco da forma).

In the case of the hollowcore floor system, escoramento could be a few telescopic props positioned at some defined distance from each other, whereas in simbramento these are combined with a grid of beams to spread loads uniformly over the floor extent. This unified approach is especially valuable in the analysis of complicated structures such as the curved bridge or multi-story parking buildings where distribution of loads has to be uniform.

In the 2026, pre-Brazilian ABNT standard regulations or ISO (international guidelines) simbramento has to be designed factoring dynamic loads of nearby machine vibrations. In smaller projects for the home, escoramento might work on its own, but simbramento’s more holistic design lowers risks in high-stakes commercial builds.

A couple levels even stay in: reescoramento is interim support after taking away the form, where as remanescente leaves some of the props still around for continued curing. Knowing these differences can assist the contractor in making the right choice, both from a time and budget standpoint.

The Historical Evolution of Simbramento Practices

The roots of Simbramento go back to ancient times, when wood scaffolds held up early concrete-like mixtures in the Roman aqueducts and Egyptian pyramids. By the 19th Century, when reinforced concrete was introduced, simbramento developed from simple timber props to the kind of engineered metal systems used today.

During the 20th century, it became standardized: After World War II reconstruction in Europe popularized adjustable steel shoring, saving labor and improving safety. In Brazil and Portugal, where “cimbramento” (similar to simbramento) became popular have been proposed innovations such as modular towers of the 1970s intended for taller structures.

Digital technology has also changed simbramento: sensors inside sets and props track load distribution on the fly, warning teams of potential weak points. AI-based predictive modeling predicts curing times based on weather in 2026, enabling quicker demolding and project completion.

Sustainability also has informed evolution — a recyclable aluminum simbramento system is now standard, and it’s packed with green credentials that meet worldwide construction certifications such as LEED. As sketches like Burj Khalifa’s construction show, simbramento made it possible to reach heights that had never been seen before — and minus the accident stories.

Simbramento Systems: Different Kinds of Simbramento From Old To New Solutions

Simbramento systems come in different materials, designs and applications. Traditional wooden simbramento, which is still used in low-budget projects as well, used props braced with nails and wires that were made of eucalyptus or pine. It’s inexpensive but laborious and relatively nonreusable.

Simbramento in metal Readings for of metallic simbramento rates includes :

- Telescopic Props: Steel tubes that can be extended up to the required height, suitable for home slabs.

- Tower Systems > For each of the groups ETEM and PERI towers, stacking for high loads in bridges or arenas.

- Flying Forms : RR table type assemblies for repetitive floor pours in skyscrapers with minimal cycle time.

Hybrid systems mix materials: Aluminum-wood composites provide light strength. In seismic regions, such as some areas of Pakistan and Turkey, simbramento uses flexible joints for shock absorption.

Among the latest varieties are 3D-printed simbramento for bespoke shapes and smart systems equipped with IoT sensors to make automatic adaptations. The choice is driven by the scale of the project — simple props work best on small sites, mega projects need an integrated tower.

Implementation of Simbramento in Projects: A Step-by-Step Approach

Simbramento begins with design: engineers simulate loads using software, specifying prop spacing (usually between one and two meters) and bracing angles. The ground is leveled and base plates are added to prevent sinking during the site preparation.

Assembly is simple: set the vertical elements, then add the horizonts and braces. Engage locks and inspect frequently for safety. The pouring of concrete must be checked for uniformity to prevent overload.

7.6 Curing time in 2026 Typically, curing is monitored by thermal imaging to observe the hardening process and subsequently allow release to open– typically after 7-28 days depending upon the mix used. Disassembly is opposite: disassemble forms and remove slowly, leaving reescoramento if necessary.

Other all-too-common errors might be quota under-estimate or faulty bracing, both of which can result in collapses. Training and compliance with standards like NBR 15696 (Brazil) are best practices.

Safety and Rules of Simbramento

Safety is key when it comes to simbramento, which has led to fatal collapses in its history. key protocols are testing the props by loading them up to one-and-a-half times expected weight and for wind bracing in open sites.

In 2026 everywhere in the world has OSHA-level requirements for PPE, fall protection, and emergency plans. And digital tools — such as drone inspections, which can pick up on weaknesses before they become problems — help.

Training courses, like those offered by the International Scaffolding Institute include training on construction of scaffolds and risk assessment. Cities with denser development, such as Karachi, where hazards are even higher, have local rules with flood-resistant features built in.

Comparisons: Simbramento and Other Support Techniques

When compared to other alternatives, such as precast concrete (which reduces the amount of simbramento needed on-site) or permanent formwork, simbramento is unequaled for custom designs and shapes but demands more labor.

| Aspect | Simbramento | Precast Concrete | Permanent Formwork |

|---|---|---|---|

| Cost | Medium (reusable) | High initial | Low long-term |

| Time | Moderate setup | Faster assembly | Integrated |

| Flexibility | High | Low | Medium |

| Sustainability | Reusable materials | Factory efficiency | Less waste |

| Best For | On-site pours | Modular builds | Specialized structures |

Simbramento excels in projects that are adaptive, while precast fits for mass production.

Real-World Case Studies and Applications

In the Panama Canal expansion, simbramento was used to brace huge lock gates against gravity during pours. Closer to home, in Karachi’s high-rises, hybrid systems cope with the monsoon.

On a 2025 bridge project in Brazil, for instance, AI-monitored simbramento reduced curing by 20 percent and saved millions. Such cases demonstrate the importance of simbramento in infrastructure optimization.

Future Trends in Simbramento Technology

Robotic assembly of simbramento could well be the norm by 2030, eliminating human error. Props can be lighter, stronger with the help of nanomaterials and workers can be trained using a virtual reality simulation.

The trends are being dictated by sustainability: biodegradable composites and zero waste designs support the UN objective. The simbramento earthquake-resistant advances in Pakistan are a priority.

FAQ: Common Questions About Simbramento

What is the main objective of simbramento?

Simbramento: Temporary bracing of formwork and concrete to maintain structural integrity while the concrete sets.

What is the difference between simbramento and escoramento?

Escoramento refers to vertical props, while simbramento is the complete integrated system with braces and beams.

What are the raw materials used in simbramento?

Steel, aluminum, wood and composites; contemporary tastes are toward metals that can be reused for longevity.

Do All Concrete Projects Need Simbramento?

Yes, if your slab of concrete or beams go horizontal (but vertical ones might require less).

What is the duration of simbramento?

Usually 7—28 days, depending on the strength of concrete and environmental conditions.

What are the dangers of not simbramento?

Caving, deformation or cracks; avoid by correct design and strict inspections.

Can simbramento be reused?

Yes–metal systems are built for re-use again and again, which saves on the reinvestment of your equipment.

What are the effects of technology on simbramento in 2026?

Precision, safety and efficiency are applied with AI, sensors and BIM.

Where do I purchase simbramento equipment in Pakistan?

There are local suppliers from Karachi that provide rentals; international brands such as PERI operate regional distributors.

What certificates should simbramento systems have?

ISO, ABNT or any other (eg PEC-Pakistan Enginearing Council) standards.

From close up investigations, this guide locates simbramento as a fundamental aspect of contemporary building. For customized guidance, see a structural engineer.